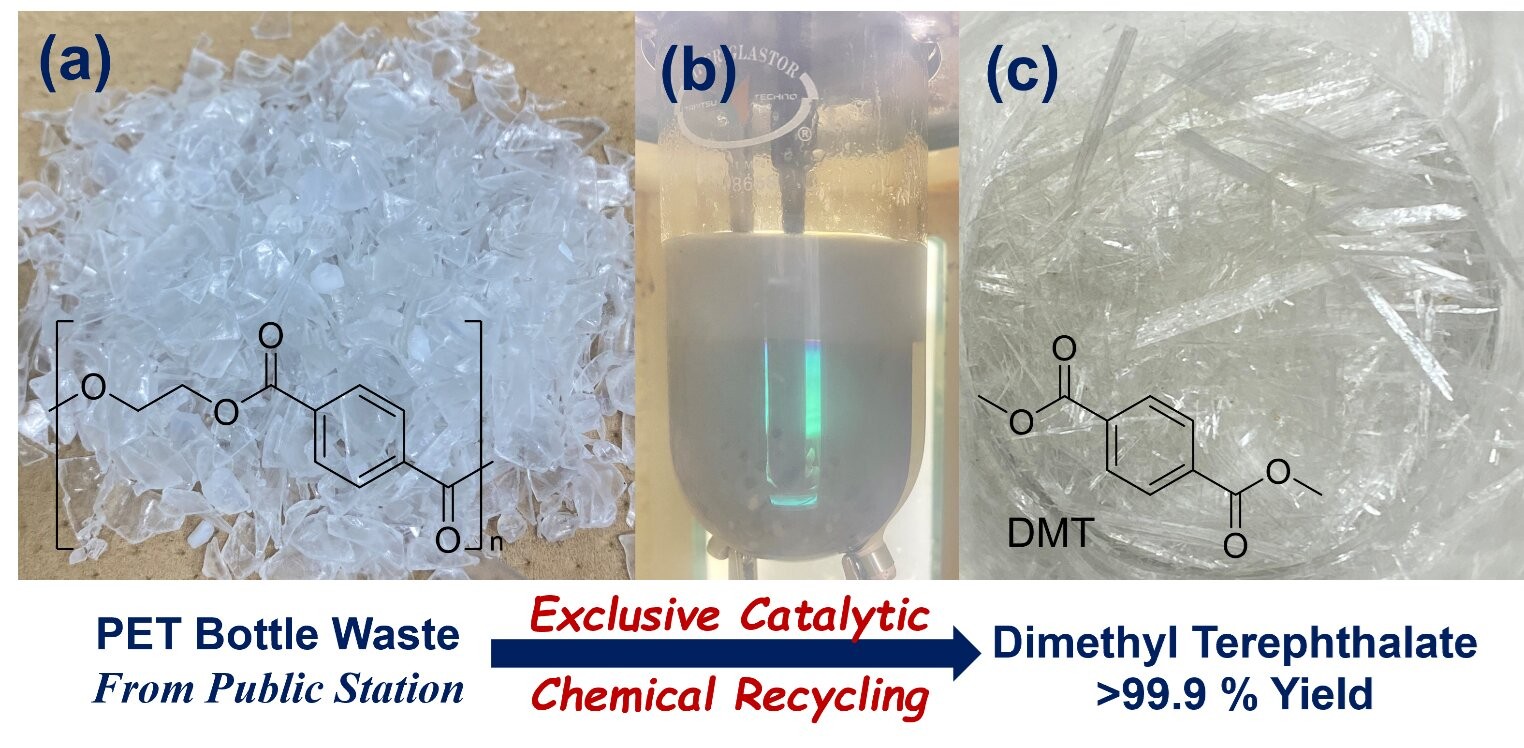

A new method for breaking down polyethylene terephthalate (PET) plastic waste – found in bottles and textiles – into valuable chemical compounds has been developed by researchers at Tokyo Metropolitan University. The process utilizes a readily available iron catalyst and common alcohols, offering a potentially significant step toward a circular economy for plastics.

The Problem with Plastic Waste

Plastic pollution is a pressing environmental issue. While mechanical recycling (reusing plastic in its original form) exists, it often degrades material quality over time. Chemical recycling – breaking plastic down into its building blocks – is seen as a more sustainable solution, but existing methods often require harsh conditions and expensive materials.

A New Approach: Iron-Catalyzed Depolymerization

The research team, led by Professor Kotohiro Nomura, has developed a method that efficiently breaks down PET into its component parts – terephthalic acid diesters – using only iron(III) chloride (FeCl3) as a catalyst and alcohols as a solvent. This approach operates at moderate temperatures (120–180°C) and avoids the need for strong acids or bases, making it simpler and more environmentally friendly than many existing chemical recycling processes.

Key Advantages of the Method

- High Yield: The process achieves nearly complete conversion of PET waste (99.7% to 99.9% yield) even when scaled up.

- Selectivity: The method selectively breaks down PET, even in mixtures with other materials like cotton or other plastics.

- Cost-Effectiveness: Iron(III) chloride is an inexpensive and widely available catalyst.

- Environmental Friendliness: The process avoids harsh chemicals and operates at moderate temperatures.

Implications for a Circular Economy

This research provides a promising solution for efficiently converting plastic waste into reusable chemical raw materials. By depolymerizing PET into its building blocks, the method enables a closed-loop system where plastic waste can be transformed into new products, reducing reliance on virgin materials and minimizing environmental impact. The method could be particularly valuable for recycling mixed plastic waste streams, where mechanical recycling is often impractical.

Funding and Research Context

The research was conducted under the Japan Science and Technology Agency (JST) CREST program, focusing on advanced polymer degradation and chemical recycling. This indicates a broader effort within Japan to develop sustainable solutions for plastic waste management.

The development of this efficient and selective chemical recycling method represents a significant step toward a more circular economy for plastics, offering a viable pathway for transforming waste into valuable resources